At the advanced age of 40 years old, I have been around for a lot of technological developments. Nothing as monumental as the discovery of fire, electricity, or the automobile, but I’ve seen my fair share of advances through the years. Some of the ideas have been great; CD’s, laptop computers, digital cameras. The list is endless of things that have come around that make our lives better, easier, or more fun. There have also been some ideas that weren’t so great; betamax, the “flowbee”, “crocs”, to name a few.

As we move into the next age of advancement we’ve begun to see the development of technology that is yet to be fully understood. We don’t know the full implications, benefits, or consequences of some of the equipment hitting the open market over the last couple of years. Specifically I am talking about drones, 3D printing technology, and the use of robotic workers.

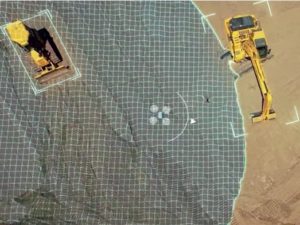

All of these technologies have been around long enough that we’ve been able to see to a limited degree, what they can do. As the cost lowers and they’re available to a wider variety of people, we get to see even more potential uses for them, both positive and negative. One area that is beginning to use both of these is the construction industry. Usually seen as slow to grasp change and quick to say “this is the way we’ve always done it”, the potential is being recognized and in a small part of our industry, it’s being utilized. Skycatch here in the United States and Komatsu machinery out of Japan have both begun using the new technology advances for various reasons in their operations.

What do you think of the potential benefits to using these on the job? Will this increase safety for our workers out there? What are some of the potential problems with utilizing this on the jobsite? I think we’re moving towards a very interesting time with all of the advances and discoveries we’re seeing out there. For further reading, check out this article about construction industry robotics.

Contact us for more information on safety training.